Stories about Brewing Beer at the Stations

Beer has been brewed at the Antarctic stations for many years; sending commercially packaged beer down south takes up valuable cargo space, thus it is more efficient to send limited quantities and brew the majority on-station.

The empty commercial beer bottles are refilled with the home brew - commonly called "Homers".

In the past, the homers was made from the basic ingredients - yeast, a starter from previous brews, malt and the usual ingredients. Nowadays, commercial home brew kits are used.

Bottling nights are a social event at the stations and many people, including non-drinkers attend.

Here are some stories about brewing beer at the stations.

The empty commercial beer bottles are refilled with the home brew - commonly called "Homers".

In the past, the homers was made from the basic ingredients - yeast, a starter from previous brews, malt and the usual ingredients. Nowadays, commercial home brew kits are used.

Bottling nights are a social event at the stations and many people, including non-drinkers attend.

Here are some stories about brewing beer at the stations.

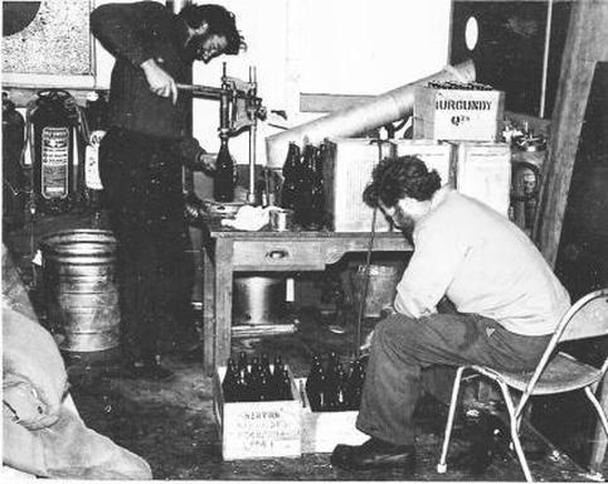

Mawson 1959

I had brought the recipe from Heard Island, where in 1954 it had been known as ‘Azorella juice’. But my grateful patients at Mawson had produced the poster seen on the door, which celebrated its virtues and ended with the punch-line “Your doctor will tell you - it’s good for you!”

The figures, left to right, are ionospherics physicist Ross Dunlop and senior meteorologist Ian Widdows, who earlier in the year had had a retrocaecal appendix removed while lying on one of the mess tables and (being a tall sort of chap) the sewing machine.

My most popular medical decision of the year was when exploding homebrew bottles on a shelf in the kitchen had obliged me to declare a Public Health Emergency, requiring that the hazard be removed forthwith by emptying the bottles in an appropriate manner.

Compliance, I’m happy to report, was 100%.

Grahame Budd.

The figures, left to right, are ionospherics physicist Ross Dunlop and senior meteorologist Ian Widdows, who earlier in the year had had a retrocaecal appendix removed while lying on one of the mess tables and (being a tall sort of chap) the sewing machine.

My most popular medical decision of the year was when exploding homebrew bottles on a shelf in the kitchen had obliged me to declare a Public Health Emergency, requiring that the hazard be removed forthwith by emptying the bottles in an appropriate manner.

Compliance, I’m happy to report, was 100%.

Grahame Budd.

Mawson 1966

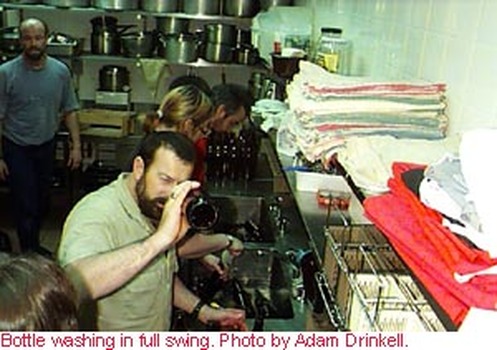

Mawson 1998

Mawson Kitchen. From front to back: Kim (Kimbo) Barnsley, Ashleigh Wilson, Andrew Brooks, Michael Keam. Photo by Adam Drinkell.

Mawson Kitchen. From front to back: Kim (Kimbo) Barnsley, Ashleigh Wilson, Andrew Brooks, Michael Keam. Photo by Adam Drinkell.

The whole 'home brew' bottling extravaganza runs over 2 weeks. Brooksy, Ron and Peter, our 'brew masters' keep an eye on the stocks and decide when to make more beer. Looking through the log books, most years bottle 3 or 4 times, capping around 400 bottles on each occasion.

We have bottled twice already this year - in February and March, to replenish stocks after summer. This was our third bottling - not so much because stocks were low (apparently we've drunk very little over winter) but more to have a large number in reserve for the summer onslaught and beyond. The bottles, which have been bought from Boy Scout Associations over the years and shipped down, number around 1700. Of these about 1000 are currently empty.

Everyone pitches in at one stage or another although there are a few 'die hards' who just love to be present at every stage of the beer making process. This includes the initial drinking of the beer, subsequent rinsing of the bottle with water and storage in the Red Shed basement.

There comes a time when Brooksy declares a 'Great Bottle Washing' night. All 400 are bought up to the kitchen, scrubbed and washed in a sodium metabisulphate solution. It's a fast moving operation with the teams of washers often 'competing' to get the most washed. There's a lot of rivalry, laughter and splashing. (Well perhaps not too much official splashing as water restrictions are in place and the plumbers have beady eyes.) The bottles are then drained, dried and stored in the basement under plastic to protect from dust.

Inspired by our enthusiasm, the brew masters then make up the beer. You probably know all this but I thought I'd outline the highly secret Mawson Home Brew Technique, codenamed MHBT.

Alternatively you could read the back of the tin can the brew kit comes in.

Generally we combine the contents of 7 cans with 7 kilograms of sugar dissolving the two in 10 litres of hot water. An additional 150 litres of cold water is then added to the 'fermenter', a 200 litre stainless steel drum with an air tight lid and fitted air lock. After mixing, 3 sachets of brewer’s yeast (thoughtfully provided by the company) are added, the drum sealed and the whole lot left to ferment for between 7-10 days. Fermentation is complete when there is no more gas bubbling in the air lock and the specific gravity of the mixture is less than 1.006.

Once this stage is reached the word goes out once again. The actual bottling of the beer is very relaxed. Firstly a teaspoon of sugar is added to a clean bottle which is then filled with fluid from the fermenter. The bottle is sealed with a metal cap (my favorite job) detailing the type and batch no, inverted four times (the worst job because juggling them is distinctly frowned upon by Brooksy) and stored until required.

Most of the home brew is lager, although we also make small quantities of stout, draught and black and tan (a mixture of lager and stout). This time cider was brewed as well.

The majority of the beer is consumed over summer when there is an influx of people (station numbers more than double) and there is much more of a party atmosphere at night. In addition we often get one or two cruise ships visiting during the summer season. The visitors usually wind up at the bar after a tour of the station and are shouted a few drinks.

We have bottled twice already this year - in February and March, to replenish stocks after summer. This was our third bottling - not so much because stocks were low (apparently we've drunk very little over winter) but more to have a large number in reserve for the summer onslaught and beyond. The bottles, which have been bought from Boy Scout Associations over the years and shipped down, number around 1700. Of these about 1000 are currently empty.

Everyone pitches in at one stage or another although there are a few 'die hards' who just love to be present at every stage of the beer making process. This includes the initial drinking of the beer, subsequent rinsing of the bottle with water and storage in the Red Shed basement.

There comes a time when Brooksy declares a 'Great Bottle Washing' night. All 400 are bought up to the kitchen, scrubbed and washed in a sodium metabisulphate solution. It's a fast moving operation with the teams of washers often 'competing' to get the most washed. There's a lot of rivalry, laughter and splashing. (Well perhaps not too much official splashing as water restrictions are in place and the plumbers have beady eyes.) The bottles are then drained, dried and stored in the basement under plastic to protect from dust.

Inspired by our enthusiasm, the brew masters then make up the beer. You probably know all this but I thought I'd outline the highly secret Mawson Home Brew Technique, codenamed MHBT.

Alternatively you could read the back of the tin can the brew kit comes in.

Generally we combine the contents of 7 cans with 7 kilograms of sugar dissolving the two in 10 litres of hot water. An additional 150 litres of cold water is then added to the 'fermenter', a 200 litre stainless steel drum with an air tight lid and fitted air lock. After mixing, 3 sachets of brewer’s yeast (thoughtfully provided by the company) are added, the drum sealed and the whole lot left to ferment for between 7-10 days. Fermentation is complete when there is no more gas bubbling in the air lock and the specific gravity of the mixture is less than 1.006.

Once this stage is reached the word goes out once again. The actual bottling of the beer is very relaxed. Firstly a teaspoon of sugar is added to a clean bottle which is then filled with fluid from the fermenter. The bottle is sealed with a metal cap (my favorite job) detailing the type and batch no, inverted four times (the worst job because juggling them is distinctly frowned upon by Brooksy) and stored until required.

Most of the home brew is lager, although we also make small quantities of stout, draught and black and tan (a mixture of lager and stout). This time cider was brewed as well.

The majority of the beer is consumed over summer when there is an influx of people (station numbers more than double) and there is much more of a party atmosphere at night. In addition we often get one or two cruise ships visiting during the summer season. The visitors usually wind up at the bar after a tour of the station and are shouted a few drinks.

Casey 2010